- 上海实验室喷雾造粒机生产厂家|实验室喷雾造粒机

详细信息

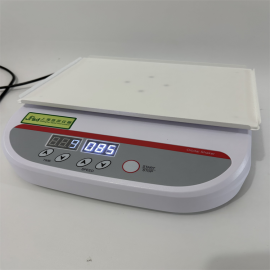

加工定制:是 雾化型式:压力式 品牌:上海旌派 型号:Jipad-2000ML 蒸发能力:3000 /h 适用物料:食品添加剂,化工,有机 应用领域:高校,研究生,科研单位 干燥塔直径:0.75 m 进风温度:200 ℃ 外形尺寸:1.2×6.5×0.5 m 高度:1.2 m 重量:113 kg 实验室喷雾造粒机

1.集成电路板设计防尘保护,密封性好。2.通讯接口8个,方便升级,电脑控制。3.控制面板液晶,定时功能,鼓风机频率可调50-70HZ,粉末状和球状都可以调,气压小就是球状,气压大就是粉末,可调:0-1mpa,

固相萃取是用来富集目标化合物,索氏提取是用来测含量的,氮吹仪是浓缩用的,喷雾式干燥机弄成干粉

主要从事销售、生产各式的实验仪器,分析仪器,主要产品小型实验室喷雾干燥机,水浴/干式/可视氮吹仪,圆形/方形固相萃取仪,二/四/六联脂肪测定仪,实验喷雾式干燥机等等。

实验室喷雾造粒机

Jipad-2000ML实验室喷雾造粒机说明:

1.将设备放置在一靠近通风位置良好的位置,并固定底部轮彀;

2.将白色聚四氟垫片放置在玻璃干燥塔的上沿,然后将玻璃干燥塔连同垫片顶在黑色法兰盘上并放正,*后用黑色大卡箍夹紧;

3.将旋风分离器顶进有红色高温标志的不锈钢出风感测处,并摆正,然后用中型卡箍将旋风分离器和干燥塔连接;(不锈钢感测可以左右移动调节,方便旋风分离器和干燥塔更好的连接)

4.Jipad-2000ML喷雾干燥用小型卡箍将冷阱和玻璃干燥塔连接、卡紧;

5.用小型卡箍将收集瓶和旋风分离器连接、卡紧;

6.以上装配前需要将玻璃干燥塔、旋风分离器、冷阱、收集瓶洗净并烘干;

7.将排风管连接好并插进有红色高温标志的不锈钢出风口感测的上沿,并保证排风管的尾部对着通气良好的地方,以防尾气对实验人员造成伤害;

8.将喷头清洗干净,并烘干保证喷头出气,出液的畅通(进料口及进气口应用四氟生料带缠紧密封);

9.将喷头插进仪器的顶部喷雾口,并旋紧固定旋钮;

10.用直径小点的蓝色PU气管连接喷头的上端及机壳右侧边上方的快速接头,连接时保证蓝色PU气管插到底;

11.用直径大点的蓝色PU气管连接喷头侧边的快速接头和右侧边上方的快速接头,连接时保证蓝色PU气管插到底;

12.插上电源线,按下绿色开关按钮(开机时,应注意红色急停处于通路状态。弹起为开,按进去为关闭),进入工作界面,点击蠕动泵按钮使蠕动泵工作。此时将医用硅胶进料管顺着蠕动泵转子的转动旋进蠕动泵,并用白色夹子固定进料管。以上工作完成后将进料管进料的一端插在喷头的进料口(以不能轻易拔下为准);

13.关闭显示屏上蠕动泵按钮使之停止转动;

14.实验时,将进料管进料的一端至于样品瓶中(实验过程中应保证样品不沉积,可在样品瓶下部用磁力搅拌达到此目的,视样品具体情况而定);

15.进入显示屏工作界面,分别点开风机、加热器、空压机、通针按钮,点击进风温度按钮设定工作所需温度并确定(设定温度时应了解溶剂沸点及溶质的熔点,温度设定值应高于溶剂的沸点并低于溶质的熔点);

16.带温度曲线趋于平稳时,点击蠕动泵工作按钮开始进料,进料速度视实验而定;

17.待试验完成后,关闭蠕动泵、空压机、通针、加热器按钮(注:此时禁止关闭风机按钮),待出风温度显示低于30度时,风机自动关闭;

18.关闭电源,断开电源线。依次取下收集瓶、冷阱、旋风分离器、玻璃干燥塔,喷头(断开蓝色PU气管时应将快速接头的蓝色部件按到底然后轻松将PU气管拔下);

19.收集好实验后的物料;

20.将玻璃部件及喷头洗净、烘干以便下次实验。

注:干燥塔、旋风分离器、冷阱、收集瓶为易碎品,安装、清洗、烘干时应轻拿轻放。

实验室喷雾造粒机Jipad-2000ML实验室喷雾造粒机产品说明:

上海旌派品牌Jipad-2000ML实验室喷雾造粒机主要适用于高校、研究所和食品医药化工企业实验室生产微量颗粒粉末,对所有溶液如乳浊液、悬浮液具有广谱适用性,适用于对热敏感性物的干燥如生物制品、生物农药、酶制剂等,因所喷出的物料只是在喷成雾状大小颗粒时才受到高温,故只是瞬间受热,能保持这些活性材料在干燥后仍维持其活性成份不受破坏。

实验室喷雾造粒机Jipad-2000ML实验室喷雾造粒机产品特征:

1、采用彩色大触摸屏操作,全自动控制和手动控制相结合,国内唯一:

2、全自动控制:一键式开机,设定喷雾工艺参数后,温度到达预定温度,蠕动泵自行启动,触摸屏上显示运行动画,运行流程清晰显示;关机时只需按停止键,机器自动安全关机。

3、手动控制:如需在实验过程对工艺参数进行调整,可方便切换至手动状态,整个实验过程彩色触摸屏动态显示(动画)。

4、关机保护功能:关机时只需按停止键,机器除风机外立即停止运行,保证设备不会因为误操作(强行关风机)而导致加热部分烧坏。

5、喷雾、烘干及收集系统采用透明的优质高硼硅耐热玻璃材料制造,使得喷雾干燥过程在无污染及*稳定的环境下进行,且使整个喷雾干燥实验进程可直接观察,为科研人员掌控实验进程及实验结果提供了*的便利,并能及时发现解决问题。所有玻璃元件易拆卸,易清洗。

6、内置进口全无油空压机,喷粉的颗径呈正态分布,流动性非常好,而且噪音非常低,小于60db,符合国家实验室噪音标准;

7、二流体喷雾的雾化结构,整机采用优质不锈钢材料精密制造,设计紧凑,无需附属设备,方便使用,历久如新。

8、为了满足用户在实验范围调节各项参数的要求,在干燥温度控制的设计上采用实时调控PID恒温控制技术,使全温区控温准确,加热控温精度±1℃。

9、为了保持样品的纯净,配备了进风口过滤器。

10、进料量可通过进料蠕动泵调节,*小样品量可达50ml。磁力搅拌器可选

11、干燥后的成品干粉,其颗粒度较均匀,95%以上的干粉在同一颗粒度范围。

12、小型喷雾干燥机针对黏性物料,设有喷咀清洁器(通针),在喷咀被堵塞时,会自动清除,通针的频率可自动调整;

13、创新的塔壁吹扫装置,物料回收率更高。

天津现货供应小型实验室喷雾干燥机,北京小型实验室喷雾干燥机

Jipad-2000ML实验室喷雾造粒机技术参数:

1、喷雾干燥机全自动控制与手动控制双重控制模式,整个实验过程彩色触摸屏动态显示(动画)

2、进风温度控制:30℃~300℃

3、出风温度控制:30℃~140℃

4、蒸发水量:1500mL/H~2000ml/h

5、*大进料量:蠕动泵可调*大为2000ml/h

6、*小进料量:50mL

7、可升级成双级分离收集系统

8、实时调控PID恒温控制技术,加热控温精度:±1℃

9、干燥时间:1.0~1.5S

10、具有关机保护功能:关机时只需按停止键,机器除风机外立即停止运行,保证设备不会因为误操作(强行关风机)而导致加热部分烧坏。

11、彩色LCD触摸屏参数显示:进风口温度/出风口温度/蠕动泵转速/风量/通针频率

12、喷嘴口径:0.5mm/0.7mm/0.75mm/1.0mm/1.5mm/2.0mm可选,并可根据要求定制

13、设有喷咀清洁器(通针),在喷咀被堵塞时,会自动清除,通针的频率可自动调整

14、喷雾干燥机整机全不锈钢制作,二流体喷雾的雾化结构,喷雾、烘干及收集系统采用透明的优质高硼硅耐热玻璃材料制造

15、内置进口全无油空压机,喷粉的颗径呈正态分布,流动性好,而且噪音非常低,符合国家实验室噪音标准;

16、整机功率:3KW/220V

17、塔壁吹扫装置,物料得率更高

18、喷雾头冷却装置(可选)

19、可直接升级成应用于有机溶剂物料干燥的氮气循环系统

20、设备尺寸:1200mm(高)×650mm(长)×500mm(宽)

国外的朋友:Lab spray granulating machine Jipad-2000ML laboratory spray granulating machine product description:

Shanghai Jing School Brand Jipad-2000ML laboratory spray granulating machine is mainly suitable for colleges and universities, research institutes and pharmaceutical and chemical enterprises producing food laboratory trace particle powder for allsolution, emulsion, suspension has broad applicability, suitable for heat sensitivematerials such as raw material drying products, biological pesticide, enzyme preparations, high temperature is only because the sprayed material just into mistsize particles in the spray, so just an instant heating, can keep the active material is not damaged after drying and still maintain its active ingredients.

Lab spray granulating machine Jipad-2000ML laboratory spray granulating machine product features:

1, using large color touch screen operation, automatic control and manual control of a combination, the only domestic:

2, full automatic control: one key start, set the spray process parameters,temperature reaches the preset temperature, the peristaltic pump to start, to touch the running animation display screen, the operation process clearly display;shutdown just press the stop button, the machine automatically safe shutdown.

3, the manual control: such as the need to adjust the process parameters in the experimental process, can easily switch to manual state, the whole experiment process color touch screen dynamic display (animation).

4, shutdown protection function: shutdown just press the stop button, the machinein addition to the wind outside the machine immediately stop operation, ensure theequipment will not be because of misoperation (forcibly closed fan) and lead toburn out heating part.

5, spraying, drying and collecting system made of transparent high heat-resistant borosilicate glass material, makes the spray drying process in no pollution and the most stable environment, and make the whole spray drying experiment process can be directly observed, the experimental process and the experimental results have provided great convenience for scientific research personnel control, and timelyfind and solve problems. All glass element, easy disassembly, easy cleaning.

Built in 6, imports of oil free air compressor, powder particle size showed a normal distribution, the mobility is very good, and the noise is very low, less than 60dB,consistent with the noise standard of national laboratory;

Atomizing structure 7, two fluid spray, the machine adopts the high quality stainless steel material precision manufacturing, compact design, no need of auxiliary equipment, convenient use, lasting as new.

8, in order to satisfy the user adjust the parameters in the experimental range requirements, using the real-time regulation of PID temperature control technology in the design of drying temperature control, make full temperature range accuratetemperature control, heating temperature control precision is + - 1 DEG C.

9, in order to maintain the purity of the sample, is equipped with air inlet filter.

10, the feed quantity can be regulated by feeding peristaltic pump, minimal samplevolume up to 50ml. Optional magnetic stirrer

Finished powder 11, after drying, the granularity is more uniform, more than 95% of the dry powder in the same particle size range.

12, mini spray dryer for viscous material, is provided with a nozzle cleaner (needle),is blocked at the nozzle, can automatically remove, through needle frequency can be adjusted automatically;

The tower wall 13, innovation of the blowing device, the material recovery rate ishigher.

Tianjin spot supply lab spray dryer, Beijing lab spray dryer

Jipad-2000ML laboratory spray granulating machine technical parameters:

1, spray dryer automatic control and manual control of the dual control mode, the whole experiment process color touch screen dynamic display (animation)

2, the air inlet temperature control: 30 to 300 DEG C

3, out of the wind temperature control: 30 to 140 DEG C

4, water evaporation: 1500mL/H ~ 2000ml/h

5, the maximum feed rate: adjustable peristaltic pump maximum 2000ml/h

6, the minimum feed volume: 50mL

7, can be upgraded into double stage separation collection system

8, the real time control of PID temperature control technology, heating temperature control precision: - 1 DEG C

9, the drying time: 1 ~ 1.5S

10, with the shutdown protection function: shutdown just press the stop button, the machine in addition to the wind outside the machine immediately stop operation,ensure the equipment will not be because of misoperation (forcibly shut the fan)and lead to burn out heating part.

11, color LCD touch screen display of parameters: the air inlet / outlet temperaturetemperature / peristaltic pump speed / wind / needle frequency

12 and the nozzle diameter: 0.5mm/0.7mm/0.75mm/1.0mm/1.5mm/2.0mm is optional, and can be customized according to customer requirements

13, a nozzle cleaner (needle), is blocked at the nozzle, will be automatically cleared,needle frequency can be adjusted automatically

14, spray dryer machine all stainless steel atomizing structure of two fluid spray,spraying, drying and collecting system made of transparent high heat-resistant borosilicate glass material

Built in 15, imports of oil free air compressor, powder particle size showed normal distribution, good fluidity, and the noise is very low, consistent with national standards laboratory noise;

16, the complete machine power: 3KW/220V

17, the tower wall cleaning device, the material yield higher

18, the spray head cooling device (optional)

19, can be directly upgraded to be used in organic solvent material dry nitrogencycle system

20, the size of the equipment: 1200mm (high) * 650mm (length) * 500mm (width)

-

-

上海旌派仪器有限公司

分液漏斗振荡器、实验室小型喷雾干燥机、水浴氮吹仪、高低温恒温槽、雪花制冰机、超声波细胞粉碎机、超声波清洗机、超净工作台、生物安全柜、脂肪测定仪、光化学反应器

上海旌派仪器有限公司 电话:187-2160-6967 手机:18721606967 地址: 上海浦江高科技园区漕河泾开发区内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。

扫一扫,手机浏览

扫一扫,手机浏览